Steam Products

Steam Traps & Temperature Control Valves

We specialize in Thermal Control products for sanitary and industrial applications designed for the temperature control and conditioning of process fluids, steam condensate recovery and freeze or scald protection. Our technologies incorporate several response methods: ambient or fluid sensing wax filled elements; bi-metallic; thermo-dynamic; and inverted bucket. Consult our specialists to improve performance, increase reliability, and reduce the operating cost of your thermal systems.

- Pinch

- Thermally Actuated

- Mechanically Actuated

- Temperature Control

- Freeze/Scald Protection

Freeze/Scald Protection

Thermally Actuated Valves. Midwest Process Controls is an authorized and factory trained distributor for Ogontz Temperature Control Valves. With self contained, wax filled elements, Ogontz control valves are ideally suited for applications that require actuation based on either ambient or internal system temperatures. Available in stainless steel or bronze construction, in direct or reverse acting mode, valves are pre-set and factory tested to open or close at your predetermined temperature set points (within +/- 3 degrees F).

Ambient Sensing Valves (External Sensing)

Typical Applications

- Steam Tracing

- Unit Heaters

- Ship Supply Lines

- Fire Systems

- Cooling Towers

- Instrument Enclosures

- Heat Exchangers

- Tanks

- Dryers

Model ST Model STE

ENERGY SAVINGS POTENTIAL ST / STE: valves monitor ambient temperature, regulating steam flow on an as needed basis, eliminating steam waste.

The ST valve eliminates the use of delicate capillaries, hazardous chemically filled diaphragms or thin-walled bellows.

It can also be used to replace or back-up existing electrically traced systems, with significant savings and equivalent temperature control.

Ideal for original or retrofit installations. The ST valve is mechanically attached to process pipe or tank wall by welding or banding.

(e.g. stainless steel worm gear pipe clamp) and thermally bonded to the wall with thermal cement, without penetrating the wall.

Process Control: ST valve sensing pipe surface temperature to control tracing. One ST can control up to 150 feet of tracing.

High temperatures and heavy condensate loads? Not a problem! Midwest Process Controls offers several options in mechanically actuated condensate traps for Sanitary and Industrial applications. Bi-metallic, Thermo-dynamic and Inverted Bucket designs are available in a variety of connection and load sizes to meet your application requirements. Ancillary products are also available including isolation and bleed valves, piping supports, and high temperature sealants.

For those applications calling for the penetration of a tank wall, our STE valve can be supplied with an actuator extension of up to 72 inches in brass or stainless steel along with an associated thermal well in those materials. For longer lengths, consult your local authorized distributor for pricing and availability.

Sizes 1/2″ to 2″ NPT, in temperature control points from 35° to 240°F

Regulation: STE valve inserted

into a thermal well for control

of tank product temperature

Oil prices …. Energy …. STEAM costs as we all know are skyrocketing

Time to prepare for winter as referenced in Chemical Processing magazine

TL Automatic Control Valve for Steam System Energy Savings

The Ogontz model TL self-actuated valve eliminates unnecessary steam waste on

winterization steam tracing, based on ambient temperature.

Steam is on below 400°F and off above 400°F

The TL valve is ideal for steam-traced lines of all types, protecting temperature sensitive instrumentation, winterizing product lines, conserving energy in unit heaters, and other applications requiring control of heat transfer media (i.e. glycol, hot oil, water, etc.) based on ambient temperature change.

The TL valve continuously monitors ambient air temperature, and regulates steam flow on an as needed basis. This eliminates steam waste and substantially reduces the possibility of overheating. Ideal for automatically controlling steam flow in steam traced lines, instrumentation enclosures, unit heaters and other applications.

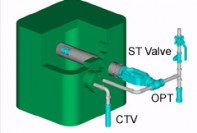

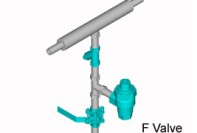

Vertical tracer line header. The TL valve controls steam to many tracer lines. An OPT is installed at the low point of the header to discharge condensate. The Ogontz F valve is used for backup freeze protection for the header.

Winterizing TracingWinterizing steam tracer lines have been employed for many years to prevent a variety of products from freezing in lines or equipment whenever ambient temperatures drop to relatively low temperatures. As shown in information found in standard chemical handbooks, many different products in addition to water must be steam traced. In general, any product with a freezing point within the normally encountered range of outdoor ambient temperatures should be traced and can be automatically and economically controlled with Ogontz TL valves.

Until the advent of the Ogontz Automatic System, winterizing tracing systems were manually operated. For example, in the traditional winterized water system, maintenance personnel were required to turn on all of the steam tracing valves at that time of the year when cold weather was coming — typically October in many of the states. These steam tracing valves would then be left open throughout the winter period, and finally turned off when the danger of low temperatures passed -probably in April.

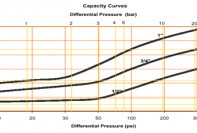

Unfortunately, there are several inherent, costly problems associated with manual operation of the steam tracing valves. The paramount problem is that leaving the steam lines open throughout an entire 5 to 9 month period is extremely wasteful. Even though ambient temperatures will drop below the freezing point of the product being protected, they will also rise and stay well above dangerous freezing conditions for hours and even days at a time. (In the Philadelphia area, for example, only 47% of the winter hours endanger a water system, Fig. 1.) Tremendous amounts of steam are wasted unless the valves are closed during these higher temperature periods. Temperatures often rise above freezing during daylight hours, making tracing unnecessary for long periods.

Another basic problem with an uncontrolled steam tracing system is the labor involved. Not only is it time consuming for maintenance crews to physically locate all valves and turn them on or off based on weather conditions, but personnel may be too busy with regularly scheduled maintenance or emergencies — or they simply forget. These steam tracing valves can become a big nuisance and even be forgotten for long periods of time. (We’ve encountered many instances where steam tracing lines were still on during the middle of the summer.)

The manual method of controlling winterizing tracing systems has another drawback involving steam waste. Whenever steam tracing lines are on and the ambient temperatures are well over the freezing point of the product, that steam is literally wasted. In addition, it robs the steam system of valuable energy that could be used in primary processing operations. Thus, heat energy is dissipated and the entire boiler-steam system is overworked — for no useful purpose. Normally, the various plant functions require the greatest amount of steam during the coldest months. Further, these months are usually also the periods of greatest waste. The purchase of extra boiler capacity can be delayed with conservation.

Energy Conservation: TL ambient sensing valve

controls steam flow to winterizing tracing lines, automatically shutting off flow when the ambient temperature rises above the desired point.

- Water lines, above ground

- Firehose lines

- Condensate lines

- Compressed air and gas lines, at drains and low points

- Process fluid lines

- Process pumps and valving, if the freezing point of the product is close to normally encountered ambient temperatures

- Instrumentation enclosures, control valves, level indicators, pressure gauges, etc.

- Unit heaters, to conserve energy

- Safety and relief valves if flow could be restricted by viscous or freezing fluid

Automatic regulation is the only way to maximize the economy of operating these systems. The Ogontz automatic tracing system incorporates valves that are all direct acting — have no pilot valves, along with their potential problems. These unique Ogontz valves are totally self-contained — requiring no external power or operating signal. Valve ports open gradually, preventing system shock. In brief, these valves eliminate the use of hazardous chemically-filled diaphragms, delicate capillaries, thin-walled bellows or potentially troublesome pilot valves.

automatic freeze protection

The AF valve offers an added degree of freeze protection for applications where rapid temperature changes and severe cold weather conditions can complicate protection efforts. The AF valve is sensitive to the effect of air temperatures below 40°F. This insures flow will be activated before pipeline or discharge freeze-up can occur.

- AF valves provide excellent freeze protection and fluid temperature control with economy.

- Automatic, fail-safe design provides reliable, unattended operation with minimal maintenance.

- Ease of installation, reduce initial installation costs.

- Valve opens and closes slowly preventing system shock.

F valves protect check valves and water lines. At ship docking facilities, water mains are equipped with check valves at supply manifolds to prevent water from flowing back into the main. When not in use, both manifolds and lines are susceptible to freezing. The AF valves establish a bleed flow to prevent freezing, while minimizing water waste. Any water line that might be exposed to freezing temperatures needs some type of freeze protection. Similarly, process equipment carrying water, such as pumps and valves, that may be subjected to freezing conditions should also be protected.

One solution to the problem of protecting water lines is to simply drain the system before freezing conditions might occur. However, in many instances this is not practical. An alternative is to open a manual valve slightly to permit some flow to drain and hope the flow is enough to prevent freezing, without losing too much water. Usually this is not practical and can be expensive because it wastes water. Manual bleeding at the proper time is subject to human error, and often results in freeze damage. Further, scarcity of water in many parts of the country and potential waste also precludes this approach.

Automatic drain valves provide another solution to freeze protection of water lines that are exposed to intermittent freezing temperatures. This approach is simple and inexpensive. One or more Ogontz Type F valves at appropriate points in the system provide the most economical way to protect water lines and other equipment from expensive freeze damage.

In applications where auxiliary heating is not really required, or in the south where only occasional cold spells occur, an automatic bleeder/drain valve is the ideal solution. These valves are inexpensive, easily installed and the inherent fail-safe design provides reliable, unattended operation. The wax-filled thermal actuator used in F valve is the same fully self-contained, temperature-actuated device employed in other Ogontz valves.

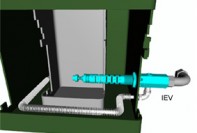

The IEV valve is a safe, low cost alternative to electric heating systems. Installed in the steam supply line, it controls the flow of steam to maintain enclosure temperature to within ± 3°F.

Available with standard pre-calibrated control points of 45°, 50°, 75°, 100° and 190°F

Allows the Use of Steam as a Heating Medium for Instrument Enclosures

The self-contained IEV valve allows steam to be an economical and reliable alternative to costly and potentially hazardous electric heating. Installed in the steam supply line, this compact thermostatic control valve senses enclosure temperature and automatically regulates the flow of steam to maintain the desired temperature.

IEV valve senses Instrument enclosure temperature regulating steam flow to maintain temperature within +/- 3 degrees

Eliminates the danger of explosion due to sparking and the expense of explosion proof controls.

- Thermal actuator controls flow of steam to instrument enclosure as needed

- Eliminates danger of overheating temperature sensitive instruments or analyzers

- Provides effective freeze-protection

- Can be safely used in all environments, no explosion proof housings or other precautions are necessary

- Calibrated actuators are interchangeable for quick easy change of enclosure temperature

- Direct acting (no pilot valve)

- High repeatability, no control point drift

- Valve port opens gradually, preventing system shock

- Temperature control points from 40° to 190°F

- Maintain enclosure temperature to within +/- 3°F of control point over a wide range of ambient temperatures and steam supply pressures

- 100% factory tested

Accurate temperature control is assured with an IEV valve. The unique thermal actuator will maintain instrument temperature within +/- 3°F of control point over a wide range of ambient temperatures, with steam supply pressures from 15 psi to 200 psi. Overheating the instrument or analyzer is effectively eliminated. IEV valves are available with standard interchangeable pre-calibrated control points of 40°, 50°, 75°, 100°, and 190°F… other control points are also available. A quick exchange of actuators is all that is required to change instrument enclosure temperature.

Self-contained Thermal Actuator

At the heart of the IEV valve is the unique solid-liquid phase thermal actuator. This hydrocarbon wax filled device actuates the valve in response to changes in enclosure temperature.

Fluid Sensing Valve (Internal Sensing)

F Series combine excellent freeze protection and fluid temperature control with amazing economy. You get maximum performance at a minimum price.

Each type F valve has unique design features that give it special advantages in specific applications. By matching the performance advantages of the valves to your specific requirements, you can eliminate costly freeze damage, reduce the waste and cost of seasonally opened block valves, protect personnel from accidental scalding at emergency shower and eyewash stations, provide increased efficiencies in cooling water control and satisfy other temperature-related flow requirements unique to your plant facilities.

DESIGN FEATURES

Ogontz F Series valves are fully self-contained, temperature-actuated devices that employ a precision, thermal actuator for reliable operation. Each valve type includes the following features:

- Fail-safe–(direct acting valve opens)

- Self-contained solid/liquid thermal actuator

- Requires no external power or remote signal

- In-line serviceability

- Insensitivity to line pressure

- High repeatability–No set point drift

- Temperature set points from 35°F to 250°F

- Available in line sizes from 1/2″ to 2″

- 100% factory tested

Typical Applications:

Freeze Protection of a Condensate System

Installed on a condensate receiver, the Type F valve provides positive freeze protection by draining the condensate system when fluid temperature approaches a preset, critical temperature.

Automatic Freeze Protection

The F valve is the most economical way to protect outdoor pipelines and vessels from expensive freeze damage. A thermal actuator automatically opens the valve before the temperature of the fluid drops to the freezing point. By bleeding the fluid in the system only when the danger of a freeze-up exists, the valve delivers positive freeze protection with minimum waste. This intermittent operation provides substantial savings in water and sewer costs, making the Type F valve an ideal, economical replacement for systems with manually operated block valves that are opened seasonally

Economic Considerations

The thermal actuator inside the valve senses water temperature. When the water temperature falls below 40°F the valve opens, draining the line to prevent freezing.

The automatic bleeder/drain approach to freeze protection provides substantial savings compared to manually operated systems. Freezing conditions can seriously damage or temporarily immobilize valuable equipment. The resultant loss of equipment or production could mean staggering financial losses. In addition, the cost of water saved by automatic freeze protection is significant.

Comparing Manual and Automatic Bleeder Valves

Manually operated bleeder valves must be left cracked open when danger of freezing is eminent. This means that water is being wasted during the entire winter. Analyzing weather shows that many hours in the winter months present no danger of freezing water. For example, in the Middle Atlantic states, during winter, about 50% of the time the temperature is above 32°F.

With automatic bleeder valves, the water flow is established only as required by weather conditions and water temperature. That is why over 50% water savings were realized when Ogontz Type F valves were installed at a large industrial facility.

In addition to protecting water lines, the automatic drain valve system provides protection to other equipment such as valves and pumps.

Using Automatic Bleeder Valves to Protect In-Line Equipment

When a ship in port replenishes its water supply, back flow preventers (check valves) are used to prevent water from surging back into the supply main, Fig. 36. At one of the largest naval bases in the world, freeze damage to the back flow preventers averaged about $150,000 a year. After installation of Ogontz automatic bleeder valves, system freeze-ups were eliminated, resulting in huge maintenance savings. And, after many years of successful operation,these automatic bleeder valves are still the primary method of protecting this equipment for both the U.S. Navy and Coast Guard.

Another ideal application for automatic bleeder valves is on solar systems using water as the heat exchange medium. Usually, thermostatically-actuated solenoid valves are employed for flow control, but the automatic bleeder valve serves as a reliable back-up device in the event of loss of power. This guarantees maximum protection for heat exchangers and piping.

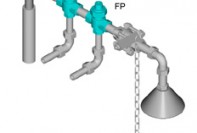

FP/FPR Fluid Temperature Sensing Valve

Automatic freeze/scald protection and fluid temperature control

Freeze/Scald Protection for Emergency Showers The Type FP valve features a space-saving, in-line design and high/low temperature sensitivity to provide positive freeze or scald protection for emergency safety showers and eyewash stations.

Freeze Protection

The low-temperature actuated Type FP valve provides the same basic freeze protection as the Type F valves, but with a straight-through flow area larger than the pipe diameter for unrestricted flow.

Scald Protection

The reverse-acting Type FPR valve is actuated by temperatures in excess of 100°F due to overheating, direct sunlight or other heat source. Discharge stops when temperature drops below 90°F full flow to shower head is also assured.

Type FP valve. The thermal actuator on this valve is inside the valve body, and responds to water temperature. Designed for in-line piping applications, the FP is available in direct or reverse action for freeze or scald protection.

Specify a full open set point in 5 degree increments.

Valve will slowly actuate within a 15 degree differential of the specified set point.

OSP AUTOMATIC SCALD & OVER TEMPERATURE PROTECTION VALVE

The OSP valve is a fluid sensing thermally sensitive control valve, fully self-contained, requiring no external power or air source. If fluid temperature was to reach the calibrated set point the valve will close, eliminating the possibility of above specified fluid temperature. Once the temperature returns to a safe point, the valve automatically reopens.

Typical Applications

High temperature sensitivity provides over-temperature/scald protection for wash-down stations, nursing homes and Industrial or commercial applications where steam or hot water are being used and mixed with cold water to produce a specific temperature

FR/FGR FLUID TEMPERATURE SENSING VALVES

Automatic Control for Cooling Systems

The reverse-acting Type FR valve is an inexpensive way to maintain optimum discharge temperatures for more efficient and economical use of your cooling media. Because of its reverse action design, the valve opens when fluid temperature rises above a preset temperature-effectively eliminating the inefficient discharge of low temperature cooling fluid.

Controlled leakage is provided through the valve for constant, true temperature monitoring. The Type FR valve is an economical way to maintain optimum operating temperature of equipment for maximum efficiency.

Type FR valve. The thermal actuator responds to fluid temperature. The valve opens as fluid temperature rises above a present level, effectively eliminating the inefficient discharge of low temperature cooling fluid. Constant control leakage through the valve ensures fast response to changing temperature conditions

APPLICATIONS:

- Compressor cooling water

- Heat exchangers

- Engine cooling water

- Cooling drums or rolls

- Platens

- Any application requiring removal of heat with any circulating

- fluid compatible with bronze or stainless steel

FDA AUTOMATIC TEMPERATURE Control Valve

The type FDA valve is fluid temperature sensing control valve. Like our standard type F valve the FDA is a direct acting valve, which closes as fluid temperature rises above the factory, calibrated set point.

The type FDA valve is specifically designed for protecting users of wash down stations from being scalded by over temperature water or steam. It accomplishes this by monitoring the supply fluid temperature. If the supply temperature rises to the calibrated set point, the valve immediately shuts off the supply eliminating the possibility of scalding an operator.

FEATURES

- Full 18-month warranty.

- Wide range of temperature set point 35° F to 250° F.

- Fail open design.

- Self contained actuator, requiring no external power or remote signal.

- Available in 1/2″ NPT

- High repeatability-no set point drifts

- 100% factory tested

Steam Traps

PROVEN TECHNOLOGY

The Ogontz Pinch Trap combines the dirt handling advantages of pinch valves with proven hydrocarbon wax technology to create the most reliable steam trap ever!

Temperature sensitive hydrocarbon wax modulates the OPT to regulate flow according to actual load requirements

A CONTINUOUS FLOW OF SAVINGS

The advanced patented design allows for a continuous flow of low velocity condensate.

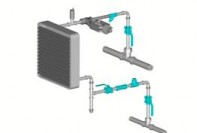

APPLICATIONS:

Drip Legs, Winterizing Steam Tracing, Process Steam Tracing, Maintaining Analyzer Sample Lines, Instrument Enclosure, Heater Discharge, Autoclaves, Radiators & All Light Loads.

FEATURES:

Excellent Dirt Handling, No Moving Parts, No Metal to Metal Seating, Freeze Protected – Self Draining, Back Pressure Insensitive, Light Load Capability, Minimal Live Steam Loss, Installs Any Position & Automatic Air Venting.

The revolutionary new steam trap from Ogontz Corporation was voted Product of the Year in the 1998 Plant Engineering Awards Competition. The Ogontz Pinch Trap (OPT) earned the Gold Award in the Fluid Handling category.

The Plant Engineering Product of the Year Awards was established to honor the most innovative and useful products introduced to the industrial plant engineering market each year. Initial entries are screened by a panel of plant engineers for publication in Plant Engineering magazine, and readers are invited to vote on their choices for the best products. “Winning the award is a significant accomplishment of which you can be justly proud”, said Richard L. Dunn, editor of Plant Engineering. The OPT is a thermostatic steam trap that uses pinch valve technology to assure exceptional dirt particle handling capability. A temperature sensitive hydrocarbon wax modulates the OPT to regulate flow according to actual load requirements.

The OPT features a patented flexible Automatic Variable Orifice (AVO) which incorporates a chemically resistant elastomer modulator, specially compounded for steam service and operated by a temperature-sensitive hydrocarbon wax. In the trap’s self-regulating action, the modulator begins to automatically pinch off flow as the wax around the modulator expands with the passage of hot condensate. As the condensate builds up and cools the wax around the modulator contracts allowing the orifice to open and create flow.

A Continuous Flow of Cost SavingsThe advanced design of the OPT allows a continuous flow of low velocity condensate, so there is no wear from cycling on and off. Since it has no moving parts, the OPT lasts more than five times longer than conventional plug and seat traps.

The Ogontz Pinch Trap surpasses all existing steam traps in dirt particle handling, reliability, and energy efficiency,” said Thomas M. Kenny, president of Ogontz Corp. “The OPT adjusts itself to each individual load condition, eliminating the on-off action and the inherent wear associated with plug and seat traps.”

The OPT also greatly reduces the cost of installing and maintaining traps, eliminates downtime and loss of product due to failed traps, has minimal live steam losses, and uses energy in the steam line at maximum efficiency before releasing condensate.

The Dirt Handling Advantages of a Pinch ValveLike a pinch valve, the OPT will close tightly even if dirt particles are in its flow path. This eliminates a failed or stuck-open trap due to dirt particles or scale.

If dirt particles start to plug up the orifice during the continuous flow of condensate, the valve will cool because of the reduced flow, the wax will contract, and the orifice will begin to open, allowing dirt particles to pass. The OPT features a much larger orifice than is typically found on other steam traps, enhancing the dirt particle and scale handling capability of the trap. Once the particles/scale have passed through the OPT, the orifice will then adjust back to its original modulated size based on the load.

New “Proven” Technology“The OPT combines the dirt particle handling advantages of pinch valves, with proven hydrocarbon wax technology to create the most reliable steam trap ever,” said Kenny. “We have cycle-tested the OPT through 3,500 successful cold start cycles, which translates into many years of successful service.”

The OPT trap meets the needs of most installations in the steam processing industry, including the very light load conditions which are most challenging to steam trap applications in the chemical, pharmaceutical, hydrocarbon processing and other industries. It can modulate down to less than one pound per hour on steam drip legs or modulate open for up to 200 lbs. per hour.

Typical applications for the OPT include: winterizing steam tracing, process steam tracing, maintaining analyzer sample lines, instrument enclosure heater discharge, autoclaves, radiators and any light loads.

The OPT was featured in a special awards section in the April, 1999 issue of Plant Engineering magazine and in the Plant Engineering booth during the National Plant Engineering and Management Show in Chicago in March, 1999.

CTV CONDENSATE TEMPERATURE CONTROL VALVE

Virtually NO LIVE STEAM LOSS

Live and flash steam losses are effectively eliminated by controlling condensate discharge temperature.

Additionally, a liquid seal minimizes live steam loss, even under extremely light load conditions.

Note: For Saturated Steam Only

CAT CONDENSATE ACTUATED TEMPERATURE CONTROL

Available in ½” NPT with standard temperature control points of 60°, 100°, 120°, 180°, 240°F.

Other set points available from 35-240°F.

MINIMAL LIVE STEAM LOSS

Live and flash steam losses are reduced by controlling condensate discharge temperature

OPTIMUM USE OF SENSIBLE HEAT

Additional energy savings can be realized utilizing the sensible heat contained in high temperature condensate. Heating tracer lines with high temperature condensate can provide additional savings without affecting heat-up rate or process temperature.

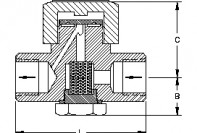

TD-300 Thermodynamic Disc Steam Trap

Incorporating a turbulence groove in the disc to reduce live steam loss the TD-300 is an all stainless steel thermodynamic disc steam trap with capacities up to 2900 lbs/hr.

Application:

Industrial Processing Equipment

Steam Tracing

High-Pressure Drip Legs

HVAC Heating Equipment

- Removable 20 mesh screen

- All stainless steel

- Vertical or horizontal installation

- Discharges at steam temperature

- Optional blow down available

- 18 month warranty