Services

On-site Inventory Management

We offer a range of inventory management services including “JIT”, Blanket Purchase Order fulfillment, “Max/Min” or “Keep Full” stocking, and Segregated Material. We can provide period specific reports and monitor inventory usage activity. We’ll customize our program to fit what works best for you. Give us a call!

Tube Fitting Training Seminar

We offer an intensive eight hour seminar on the development and theory of tube fittings and their relevance to modern fluid systems. This seminar is ideal for installers, engineers, designers, automation, instrumentation and maintenance personnel.

Covered Topics:

- Tube VS. Pipe – Differences and Advantages

- Functions of Tube Fittings

- Development of Tube Fittings from Sweat Type Through Compression to Hy-Lok

- Tubing Specification, Selection and Identification

- Tubing Care and Handling

- Assembly and Re-assembly of Hy-Lok Tube Fittings 1” or Less

- Use of Pre-Swaging Tools

- Assembly of Fittings Over 1” Including EZY-MAT Tool Use

- Tube Cutting and De-burring

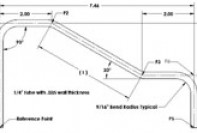

- Tube Bending – Theory and Practice

- Planning and Installation of Tubing runs

- Use and Misuse of:

- Tube Adapter Fittings

- Port Connectors, Plugs and Caps

- Positionable SAE Fittings

- Use of Zero or No-Axial Clearance Fittings

- Pipe Threads – Sealing Methods, Specification Identification and Dimensional Differences

- Thread Sealants and Galling

- Interchangeability

- Safety Precautions – Summary

Benefits for an Installation Seminar?

Our product knowledge and associate training is well known in the industry. When problems arise, regardless of brand or where purchased, we tend to be called in and consulted. Of the thousands of trouble shooting calls we have made over the last 15 years, more than 90 percent are due to installer error. Tube and fitting installation is all too often regarded as a simple procedure with little or no consequences associated with improper techniques. Experience tells us otherwise. Leaks, downtime, blowouts, and personal injury can occur when safe installation practices are not followed. We are all interested in reducing operating costs by achieving incident free operations. This installation seminar will do just that

Quality Training from Industry Experts

Midwest Process Controls has brought together a team of professional staff with vast experience in control and instrumentation, process, and hydraulic systems in the following industries: Petro-chemical, analytical, R&D, marine, off-shore, power generation, aerospace, semi-conductor, pharmaceutical, and bio-technology.

Our people are renowned for offering professional advice and promoting Total Quality service. The Training Services Division has been established to supplement this with an appropriate level of professional installation training.

Hy-Lok Quality Control Quality cannot be sacrificed by any means.

All Hy-Lok valves, Hy-Lok tube fittings, Hy-Lok threaded and clean fittings and Bite type fittings are manufactured under our strict Quality Control Program. We have obtained ISO 9001 Certificate and Quality System Certificate from ASME. We also have certificates from Det Norske Veritas (DNV) and Germanischer Lloyd (GL). Furthermore, we are one of a few valve and fitting manufacturers in the world holding the Nuclear Certificates as material manufacturer and supplier. These certificates cannot be obtained overnight. They are the results of our extensive and continuing efforts for quality control, covering virtually all our activities; product design, material procurement, manufacturing, cleaning and packaging, inspection, testing, and after-sales services..

Raw Material Management

The base materials are one of the key factors determining the quality of valves and fittings which manufacturing processes involves forging, fine machining, heat treatment, etc. Using poor quality base materials can affect the quality, reliability, and service life of the products. Hy-Lok products are made from the highest quality materials obtained from the most reliable suppliers around the world Material Certificates are readily available upon request from us or from the base material suppliers. Our efficient, stock of raw materials enables a short delivery.

HCT (Heat Code Tracability)

Hy-Lok has implemented a Heat Code Tracability system. Our HCT is unique because it not only contains the raw material information, but also more detailed process and technical information, if necessary, each product can be traced back for the verification of materials, processes, etc.

Pressure Test

Our valves are 100% factory tested with nitrogen normally at 1000 psig to the max leak rate of 0.1 SCC/M Upon client’s specific request, valves or fittings can be tested under severe conditions; e.g. at higher pressure, and/or at elevated or very low temperatures, with vibrations, etc.

Close Dimensional Control

At Hy-lok, all dimensions are closely checked and controlled by each operator according to our special in-process-quality-control procedures separate form the QC inspection. This is done accurately with inspection gauges which are specifically designed and periodically calibrated. Each operator knows whether the process is in exact control or not. Defects or problems, if any, are detected and corrected on the spot immediately. By doing so, we have achieved the following:

- Dimensional Tolerance of 1/1000 inch

- Threads tolerance acc 2A, 2B, as per ASME B1.1

In addition, we have minimized the failure rate and downtime and maximized pass rate and productivity, which in turn has made our products most competitive in price.

In order to keep gas or liquids clean, the inner surface of the fittings must be smooth. The inner surface of the fittings must be smooth. The inner surface of each Hy-Lok Valve and fitting is fine machined and tested with special instruments.

Fabrication

Services include design, proto-type, fabrication, and assembly of your equipment or process components. We can build to your design or start from scratch using our extensive process component & equipment experience in offering the right solution to your needs. Fabrication of components and systems from stainless steel, steel, aluminum, and other alloys by certified craftsmen ensure complete satisfaction!

Energy Conservation

We can dramatically reducing energy costs and improving the bottom line? We offer cutting edge technology and proactive program oriented solutions to help improve operating efficiency and reduce energy costs.

- Energy Savings Program

- Tube System Performance Survey

- Process Fluid Temperature Control

- Instrument & Control Solutions